How to Make Damascus Steel Bars for Knife Making: A Complete Process

Introduction

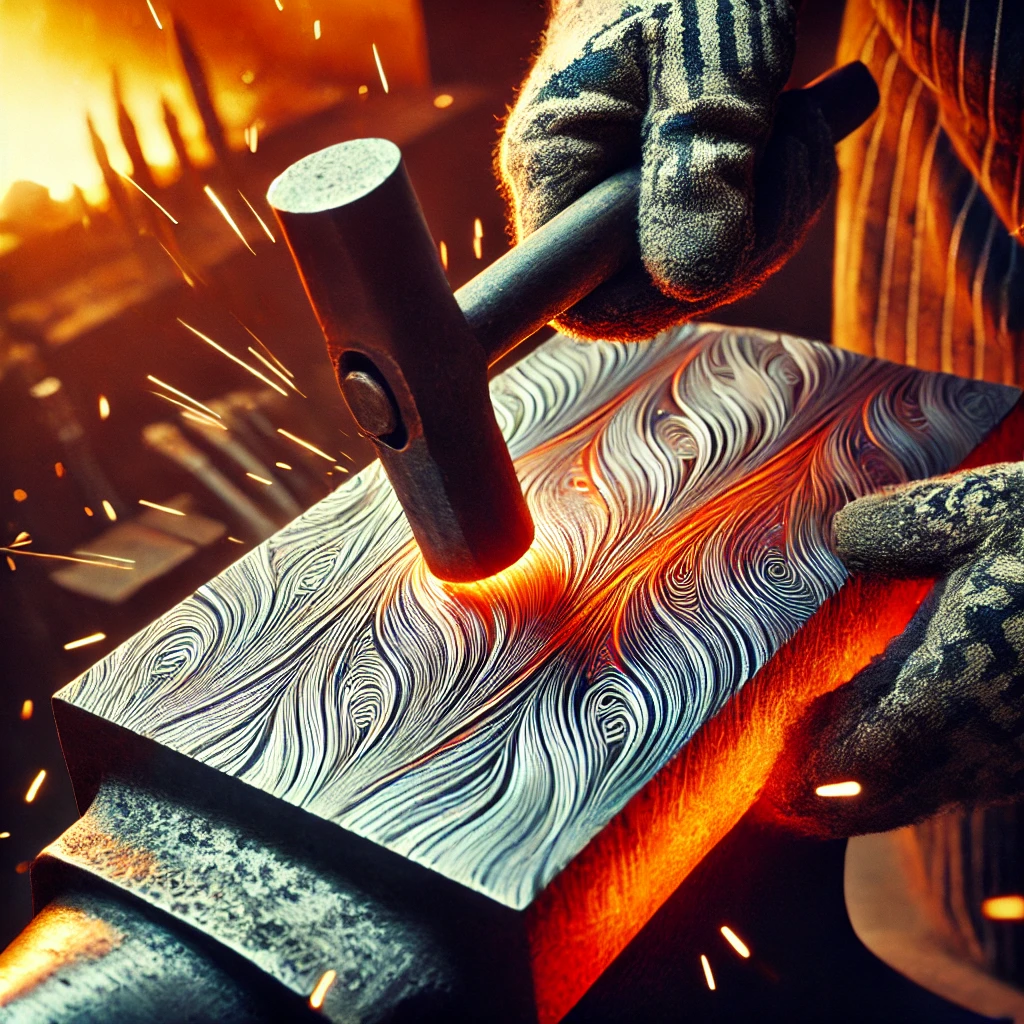

Damascus steel is renowned for its unique patterns, strength, and sharpness, making it a popular choice for knife making. Creating Damascus steel bars involves combining different types of steel through a process of layering, forging, and etching. This guide will walk you through the complete process, covering tools, materials, techniques, and safety tips.

Thank you for reading this post, don't forget to subscribe!

Table of Contents

- Tools and Materials Needed

- Preparing the Steel

- Creating the Initial Billet

- Forging and Folding the Billet

- Drawing Out the Bar

- Heat Treating the Damascus Steel

- Acid Etching for Pattern Development

- Safety Tips

- Pros and Cons of Damascus Steel

- Conclusion

1. Tools and Materials Needed

Tools:

- Forge or kiln

- Anvil

- Hammer

- Belt grinder

- Welding equipment

- Tongs

- Clamps

- Safety gear (gloves, goggles, apron)

Materials:

- High carbon steel (e.g., 1095)

- Low carbon steel (e.g., 15N20)

- Flux (borax)

- Acid (ferric chloride or muriatic acid)

- Water and oil for quenching

2. Preparing the Steel

Select high carbon and low carbon steel types for their contrasting properties. Cut the steel into strips of equal length and width. Clean the steel pieces thoroughly to remove any dirt or rust.

3. Creating the Initial Billet

- Stacking the Steel:

- Layer the steel strips alternately (e.g., 1095 and 15N20) to form a stack.

- Aim for 10-20 layers for the initial billet.

- Welding the Billet:

- Weld the edges of the stack to hold the layers together during forging.

- Ensure the welds are secure to prevent layers from separating.

4. Forging and Folding the Billet

- Heating the Billet:

- Heat the billet in the forge until it reaches a bright orange or yellow color (about 2100°F or 1150°C).

- Applying Flux:

- Sprinkle borax flux on the billet to prevent oxidation and facilitate welding.

- Forging the Billet:

- Hammer the billet on the anvil to weld the layers together.

- Fold the billet in half and repeat the heating, fluxing, and forging process.

- Continue folding and forging until you achieve the desired number of layers (commonly 200-300 layers).

5. Drawing Out the Bar

- Shaping the Bar:

- Once the desired layer count is achieved, draw out the billet to the desired thickness and length for the knife making.

- Refining the Shape:

- Use a belt grinder to refine the shape of the bar and ensure even thickness.

6. Heat Treating the Damascus Steel

- Normalizing:

- Heat the bar to a critical temperature and allow it to cool slowly to relieve internal stresses.

- Hardening:

- Heat the bar to a critical temperature again and quench it in oil to harden the steel.

- Tempering:

- Temper the bar by heating it to a lower temperature (around 400°F or 200°C) and allowing it to cool slowly to reduce brittleness.

7. Acid Etching for Pattern Development

- Preparing the Acid:

- Mix ferric chloride or muriatic acid with water (follow manufacturer’s instructions for the correct ratio).

- Etching the Bar:

- Clean the bar thoroughly and submerge it in the acid solution.

- Allow it to soak until the desired pattern develops (usually 5-30 minutes).

- Remove the bar from the acid and neutralize it in a baking soda solution.

- Finishing:

- Rinse the bar with water and dry it completely.

- Apply a protective oil or wax to prevent rusting.

8. Safety Tips

- Always wear protective gear (gloves, goggles, apron).

- Work in a well-ventilated area.

- Handle acids with care and follow proper disposal guidelines.

- Keep a first aid kit nearby.

- Be cautious with hot materials and sharp tools.

9. Pros and Cons of Damascus Steel

Pros:

- Unique, attractive patterns.

- Excellent strength and durability.

- High edge retention.

Cons:

- Time-consuming and labor-intensive process.

- Requires specialized equipment and skills.

- Can be expensive due to materials and craftsmanship.

Conclusion

Making Damascus steel bars is a challenging yet rewarding process that combines artistry

Discover more from Knives Trade Blog

Subscribe to get the latest posts sent to your email.